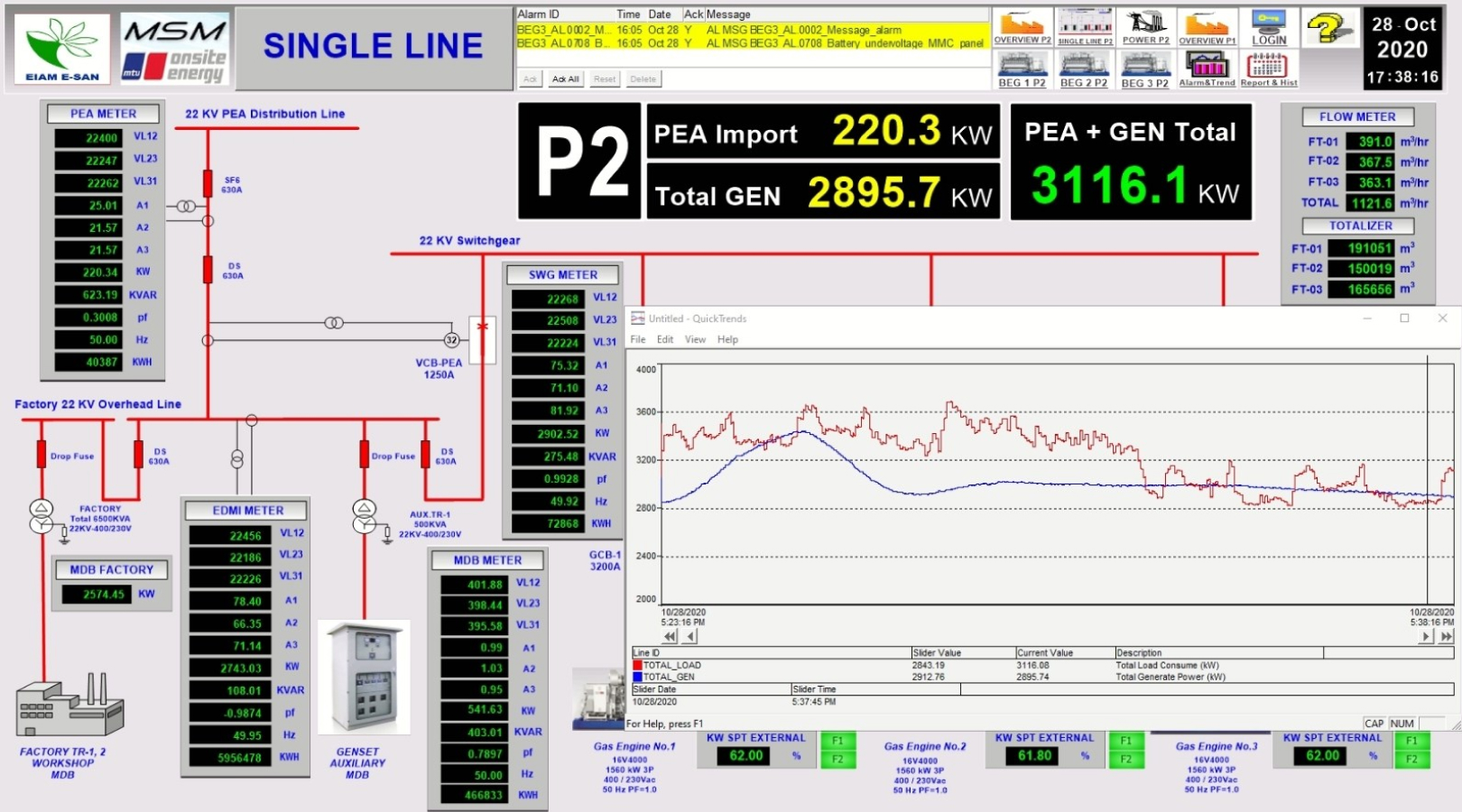

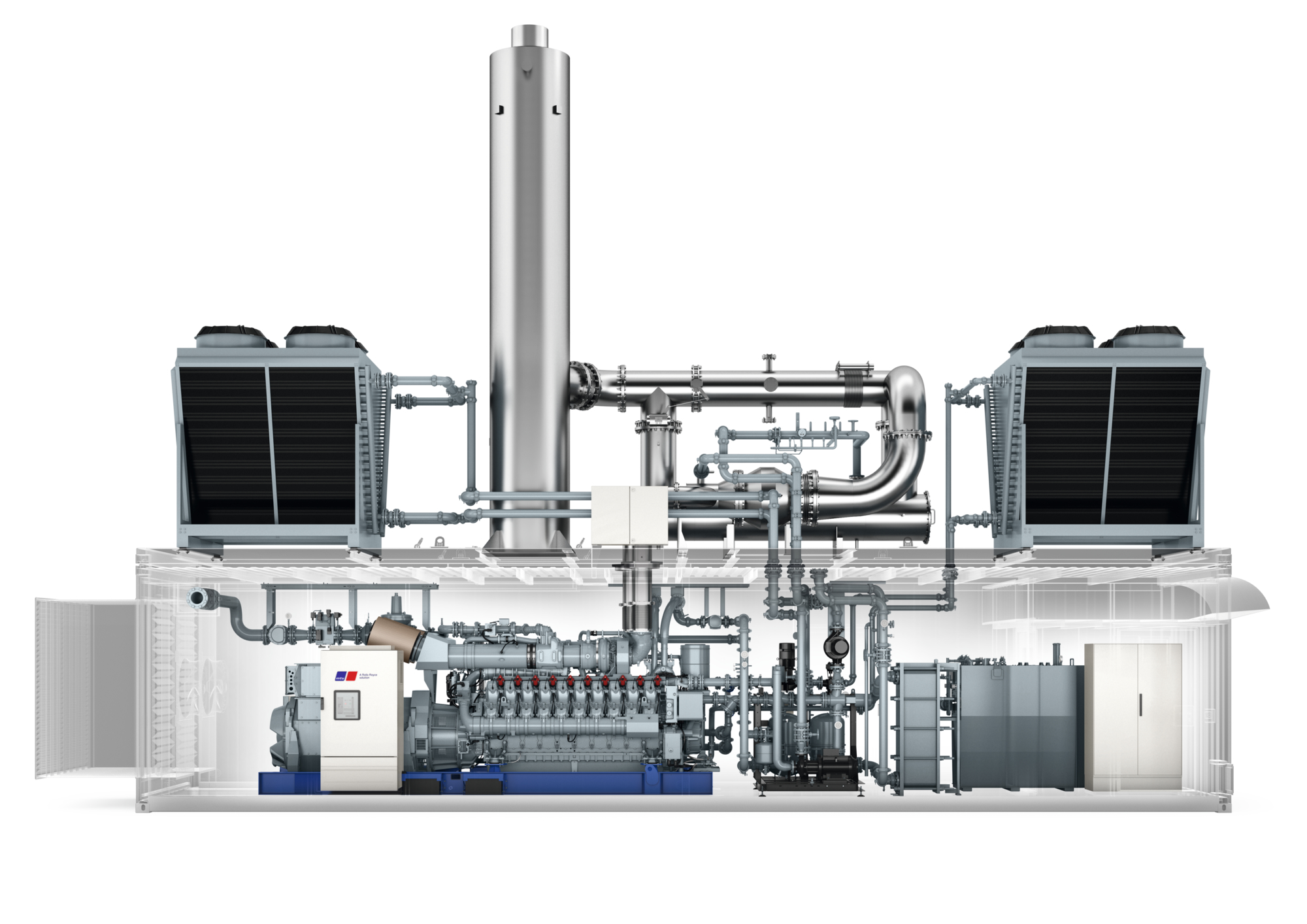

CHP Plant Design & Construction

We can customized the CHP unit to the client's requirements. We provide feasibility studies for budgetary purposes and project management during construction. The electrical power produced can be for captive use or exported to grid under a PPA. The heat recovered from the engine cooling water and exhaust can be converted to

- Hot water / Hot air with heat exchangers

- Chilled water with absorption chillers

- Steam with HRSG boiler